Understanding Embodied Carbon Part 2: The Tin Barn Retrofit Case Study

Continuing our series on understanding embodied carbon, this case study examines our recently completed project, The Tin Barn, located in a picturesque rural village. It demonstrates how embodied carbon considerations can be applied practically and the positive outcomes from thoughtful design and planning. We're pleased to say that this Retrofit sets a new example for sustainable design and construction and stands out as an exemplary model of low embodied carbon, demonstrating the potential of sustainable architecture.

The Tin Barn Retrofit achieved the rigorous EnerPHit certification – a standard for retrofitting existing buildings to achieve high levels of energy performance. The building has significantly reduced operational energy demand while enhancing indoor comfort and air quality. From high-performing building fabric to draught-free/airtight construction, every detail was executed to optimise energy efficiency without compromising on aesthetics or functionality.

Embodied Carbon and Its Significance

As we explained in our previous blog, embodied carbon refers to the total CO2 emissions generated during the extraction, manufacturing, transportation, construction, and disposal of building materials. Unlike operational carbon emitted during the building's use, embodied carbon is locked in from the outset. Reducing embodied carbon is crucial for combating climate change, as it accounts for a significant portion of a building's overall carbon footprint.

Applying Embodied Carbon Considerations

We approached The Tin Barn project with a clear vision: to create a beautiful, functional space that minimises environmental impact from the ground up. This meant integrating circular economy principles, prioritising locally sourced and sustainable materials, and employing innovative construction techniques to reduce carbon emissions.

Key Strategies for Reducing Embodied Carbon

One of the most significant factors in reducing embodied carbon is the choice of materials. We opted for materials with low environmental impact, such as recycled and reclaimed materials, bio-based insulation and locally sourced materials.

The scheme incorporates a substantial amount of bio-based materials across various components, including external cladding, internal finishes, structural elements, and insulation. Bio-based materials were prioritised and utilised wherever possible, highlighting the project's commitment to sustainability and reducing environmental impact. This approach not only enhances the building's ecological footprint but also promotes the use of renewable and natural resources in construction.

Environmental impact of different materials used in construction. Image source

Our choice of materials also reflects our consideration of carbon sequestration:

“‘Carbon Sequestration’ is the process by which carbon dioxide is removed from the atmosphere and stored within a material – e.g. stored as ‘Biogenic Carbon’ in ‘Biomass’ by plants/trees through photosynthesis and other processes.” LETI

Sequestering carbon that has been removed from the atmosphere in buildings and products is a key way of tackling climate change. This can be done by taking plant matter such as wood, cork, hemp and algae that has captured atmospheric carbon via photosynthesis and using it directly. Alternatively, it can be turned into other materials that store carbon more permanently. These materials absorb carbon dioxide during their growing phase and continue to store it within their structure, offering us a way to reduce our carbon footprint effectively and efficiently.

At its core, the project embraced sustainability by repurposing an existing structure rather than embarking on new construction. The dilapidated tin barn, once a relic of agricultural history, now stands as a testament to adaptive reuse and environmental stewardship.

Central to the project's sustainability narrative is the extensive use of timber sourced from sustainably managed forests. This choice not only minimised the project's embodied carbon footprint but also supported sustainable economies.

We designed with the layers of the buildings in mind. The elements that need to last for hundreds of years without replacement have tended to use more carbon such as steel & glulam structural elements. Layers of the building that tend to be replaced more frequently like surface finishes use low embodied carbon materials like natural sisal carpets and wood panelling.

Instead of demolishing the existing buildings and starting anew, the project embraced adaptive reuse, breathing new life into disused structures. By repurposing the barn, the project minimised the need for new materials and avoided the environmental impacts associated with demolition and disposal. The existing steel structure of the tin barn was encased in a timber frame, working in structural symbiosis.

The fallen dry-stone walls were riddled and sorted into sizes, which enabled the stonemason to reuse them within the building alongside locally sourced new stone from the same quarry.

The offcuts of larch cladding from both the stables and tin barn were kept on site and have been creatively reused to clad over a boundary wall, with the introduction of untreated larch to infill the slight shortage.

The agricultural paraphernalia, such as water tanks, have persevered on the site and are used for rainwater harvesting. Dilapidated structures and timber doors have been repurposed into garden seating and planters.

Throughout the renovation process, the project team prioritised resource optimisation by carefully assessing and repurposing salvaged materials from the original structure whenever feasible. This approach not only reduced waste but also minimised the need for new materials, thereby conserving resources and reducing the project's environmental footprint.

Performance and Impact

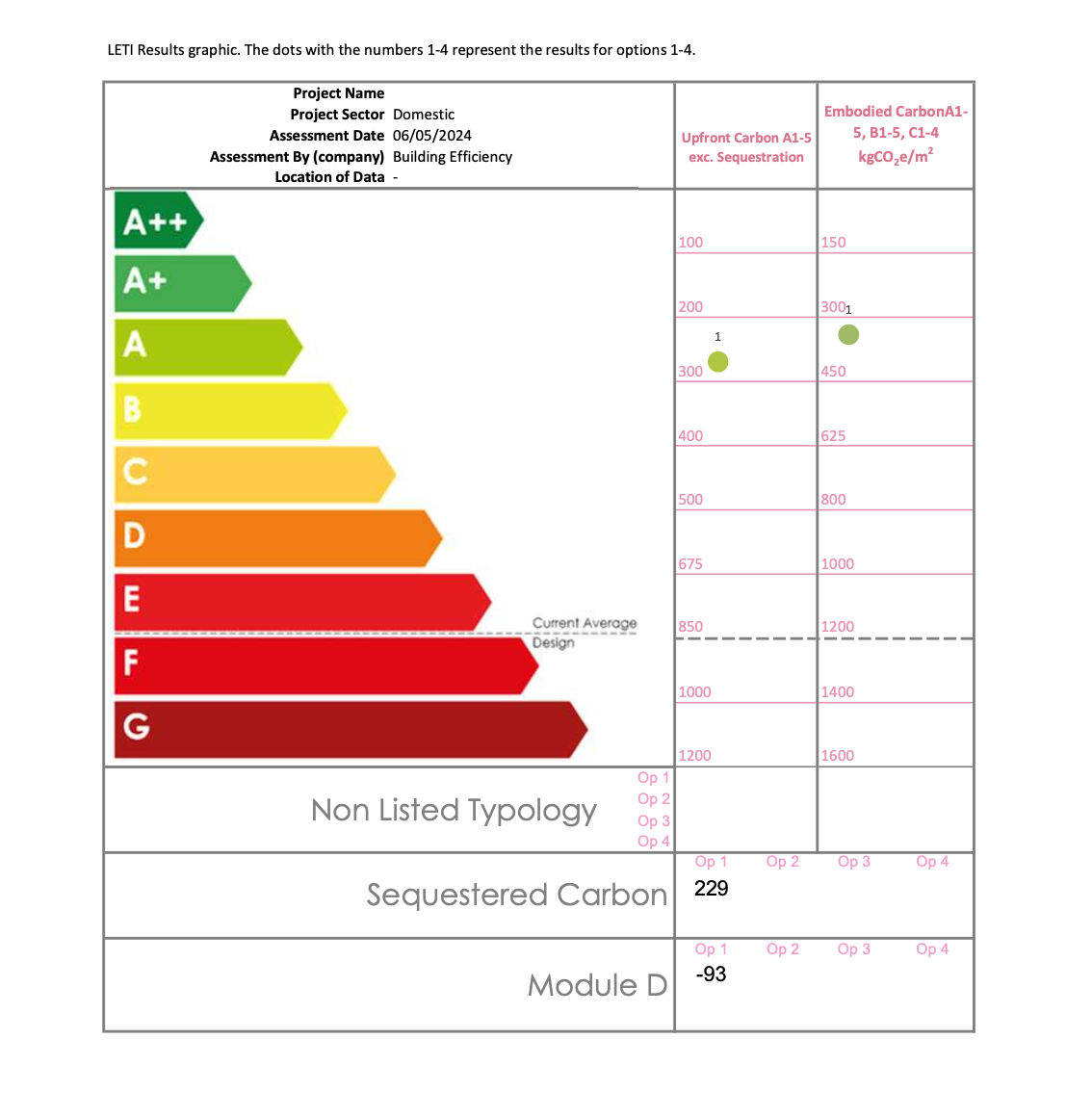

As a result of these careful considerations and construction techniques, The Tin Barn's embodied carbon footprint is significantly lower than that of conventional buildings, standing at an impressively low 347 kg CO2e/m2 GIA, almost half of the RIBA 2030 target of 600 kg CO2e/m2 GIA and just 47kg over the LETI 2030 target.

The Tin Barn is an example of how thoughtful design and sustainable practices can significantly reduce embodied carbon. This project not only provides a beautiful and functional space but also sets a precedent for future construction projects aiming to minimise their environmental impact. As the industry continues to grapple with the challenges of climate change, The Tin Barn offers a roadmap for how to build responsibly and sustainably.

By embracing circular economy principles and prioritising low-carbon materials and techniques, it is possible to create buildings that are not only environmentally friendly but also enhance the well-being of their occupants and the surrounding community.